Products

Index > Products > Vented Solid Tire > Solid Loader Tires > Tires For Loder

Quick Details

Maintenance measures for wheel of loader

As a professional loader tire manufacturer, we suggest that the following aspects should be done in the process of using and maintaining the loader tires:

1.Shovel materials before the operation, the driver should be bucket close to the ground, the work area clean scattered materials, especially in the old building demolition site operation loader, must confirm the operation site no bare steel high off the ground to prevent foreign bodies, and stabbed the tire.

2. In the rock site use tire special protection chain, reduce the damage of rock materials such as tyre.

3. In view of the same condition, the front axle drive tire wear greater than the rear axle drive tires, can regularly change the front axle tire to the rear axle use. Front axle drive tires as much as possible to maintain good color, generally more than 6 or more.

4. In order to reduce the cost of use, the rear axle drive tires can choose refurbished tires, and the front axle drive tires should be avoided.

5. The wear degree of coaxial tires should be approximately the same, that is to say, the principle of simultaneous replacement should be taken as much as possible. When the loader is traveling straight, because of the difference of drivers on both sides of the rolling radius of the coaxial wheel, the drive axle main reducer speed difference (or on both sides of the tire cannot make loader realize straight line driving increases the burden of work), differential.

6. Tyre penetrating wound, except under emergency conditions can use the tyre cavity laying cushions, must use fire to fill completely closed through the wound repair method. Otherwise, the untreated tyre "cut", will be repeated on the part of the extrusion tube, resulting in tube breakage.

7. If the tire tread is worn out, such as the emergence of local bare line layer, you should replace the tire in a timely manner. A tire carcass at this time remained relatively intact, can be refurbished, two tube intact, can only replace the tire. Once the replacement caused by not timely in the tire, and tire will also be scrapped, only in accordance with the handling of waste tires, The loss outweighs the gain.

8. The driver should correctly install the tire during the replacement and repair of the tire to ensure that the tire tube has no folding and clamping tires. Replace the inner tyre, in order to prevent the inner tyre and the pad adhesion phenomenon and the hub, can apply talcum powder in the tyre cavity. Before the talcum powder, must use cloth to clean the water, sand and other inner tyre, especially sand and other impurities if the inclusions in tyre, due to repeated extrusion, the tube will be damaged. In addition, the locking nut which is connected with the inner tube of the new pneumatic tube is generally loose, and the wrench should be tightened before the installation.

9. Loader tire, should be in place to replace, otherwise, even if it is a short distance running, can also cause damage to the inner tube and scrap tire, reduce the service life.

10. The loader driver should regularly check whether the tire pressure meets the requirements. According to the seasonal variation, the tire pressure should be adjusted properly, and the summer temperature is higher, and the tire pressure can be appropriately reduced. When pneumatic tyres are inflated, the barometer must be used to avoid the sensory operation.

11. The number of tires used by loaders should not be too much. Because tires belong to rubber products, with the extension of storage time, it is easy to oxidize outside and shorten service life. The longer the storage time is, the higher the oxidation degree is, and the longer the tire with longer storage time, the grey color appears on its outer surface. Buyers can also determine the length of inventory. In addition, tires should be stored in a dark and dry environment, and high temperature conditions can also accelerate the aging of tires.

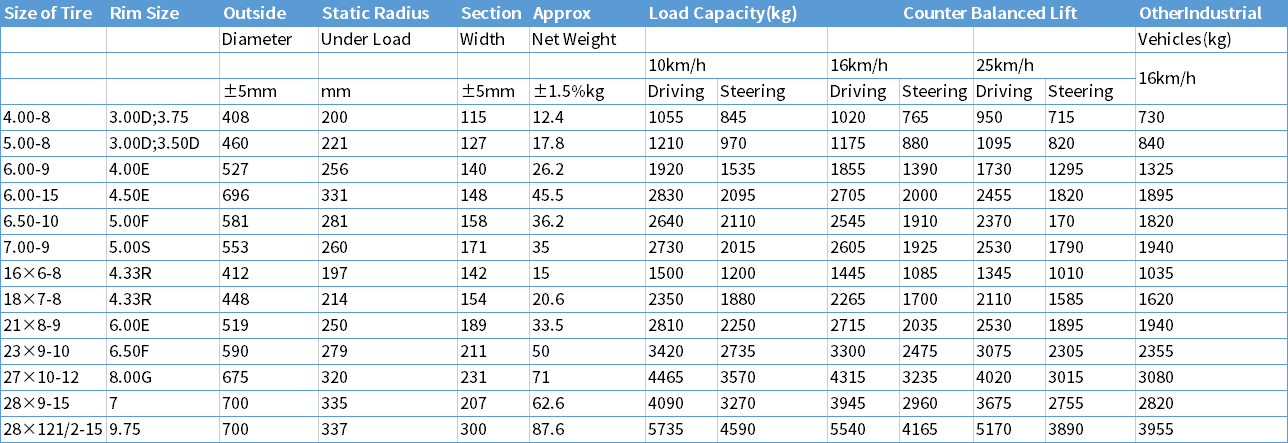

Quick Details

There are many specifications about this tyre, please contact with our company's customer service staff for details.

Products Specification

Service

-

Training and Use

We will supply friendly English operation manual and installation. Customer is warmly welcomed to visit our factory for free training. We can also send engineer to customer¡¯s country to supply training.

-

Guarantee & After-sale Service

We supply one year warranty under normal use and lifetime technical support.We can provide engineers overseas training.

-

Payment Terms

1.T/T in advance;

2.West Union: we can accept small payment(below $3000), but the banking charges shall be paid by the buyer;

3.L/C is acceptable if the amount is big. Please issue the L/C draft for our confirmation

-

Documents after shipment

We will send original documents to you by DHL, including Packing List, Commercial Invoice, Sales Confirmation, Bill of Lading, and other certificates as required by customer.